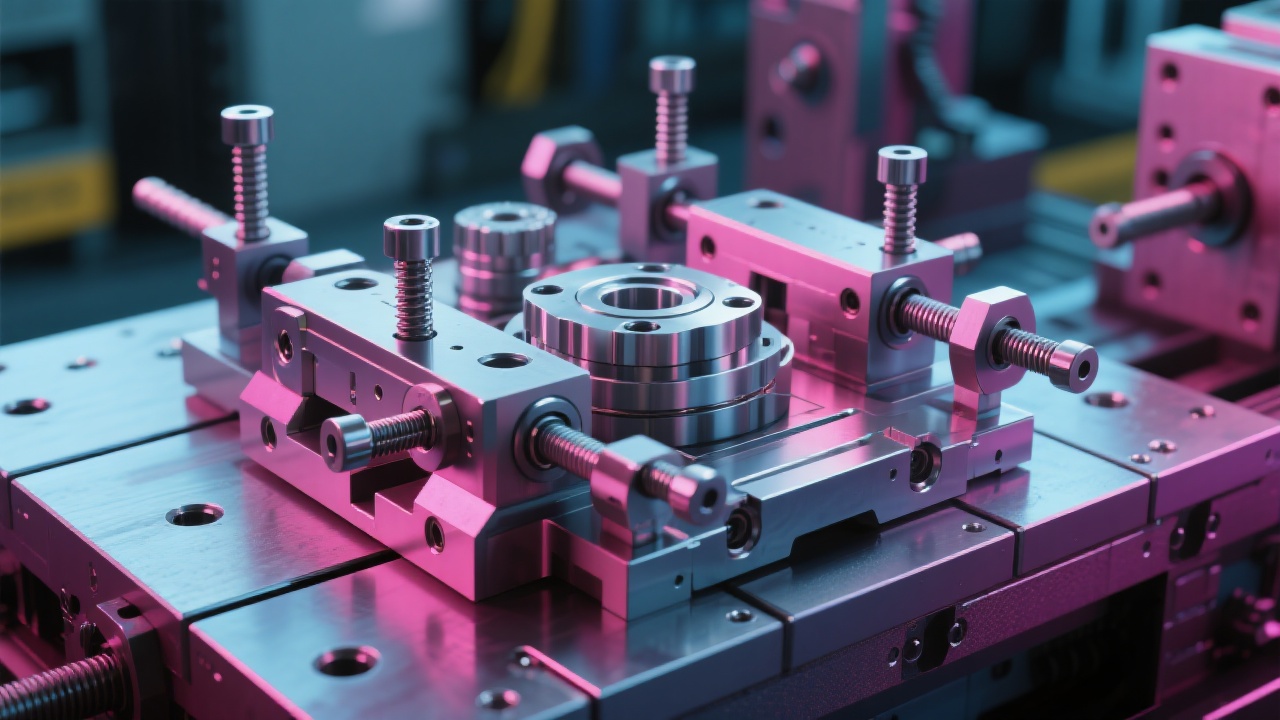

Graphite electrodes and precision graphite parts play a crucial role in various industries, including electronics, aerospace, and automotive. However, achieving high yields in the micro - machining of graphite electrodes has always been a challenge for many manufacturers. This article provides a comprehensive guide to the key process steps for improving the yield of graphite electrode micro - machining, covering everything from CAD modeling to programming.

Graphite micro - machining often encounters problems such as poor surface quality, low dimensional accuracy, and difficulty in processing micro - grooves and sharp corners. For example, in a certain graphite processing factory, when processing micro - grooves on graphite electrodes, the yield was only about 60% due to tool wear and vibration. Through the application of CAD modeling and optimized tool path strategies, the yield was increased to over 85%.

To address these issues, we need to start from multiple aspects. First, in CAD three - dimensional modeling, we should optimize the model to ensure that the design is reasonable and easy to process. Then, select the appropriate tool path strategy according to the characteristics of the graphite part. For example, using a spiral tool path can reduce tool wear and improve processing efficiency.

Taking a systematic approach, we start from CAD three - dimensional modeling optimization. In the CAD modeling stage, accurate feature recognition is crucial. By identifying the features of the graphite part, such as micro - structures, grooves, and sharp corners, we can better design the tool path. For example, when processing a graphite part with a sharp corner, we can use a small - diameter tool for fine - machining at the corner to ensure dimensional accuracy.

When it comes to CNC programming, we need to consider factors such as tool path design, dynamic anti - vibration compensation, and parameter optimization. For instance, setting appropriate anti - vibration compensation parameters can reduce the impact of vibration on the processing quality. In a case study, after adjusting the anti - vibration compensation parameters, the surface roughness of the processed graphite part was reduced by 30%.

Tool path design is a key factor in graphite micro - machining. Different tool path strategies, such as parallel, contour, and spiral paths, have different effects on processing quality and efficiency. For example, a parallel tool path is suitable for large - area rough machining, while a contour tool path is more suitable for finishing the outer contour of the part.

Dynamic anti - vibration compensation technology is also essential. By adjusting parameters such as feed rate, spindle speed, and cutting depth, we can reduce vibration and improve processing stability. In addition, different graphite materials have different processing characteristics. For example, natural graphite is relatively soft and easy to process, but it has a higher porosity, while artificial graphite has higher density and hardness, which requires more precise processing parameters.

Natural graphite and artificial graphite have different processing characteristics. Natural graphite has a lower density and is more prone to chipping during processing. Therefore, when processing natural graphite, we need to use a lower feed rate and spindle speed. On the other hand, artificial graphite has a higher hardness and better thermal conductivity, but it is more likely to cause tool wear. We need to select appropriate tools and adjust processing parameters accordingly.

Here is a comparison table of the processing characteristics of natural and artificial graphite:

| Graphite Type | Density | Hardness | Processing Difficulty | Tool Wear |

|---|---|---|---|---|

| Natural Graphite | Low | Low | Medium | Low |

| Artificial Graphite | High | High | High | High |

Throughout this article, we have used real - world cases and data to support our arguments. For example, in a graphite processing project, by applying the methods described in this article, the production efficiency was increased by 40%, and the processing cost was reduced by 20%. These data demonstrate the practical value of the proposed methods.

Now, let's think about it. Have you encountered similar problems in your graphite micro - machining process? How did you solve them?

To sum up, by following the key process steps from CAD modeling to programming, and considering the processing differences of different graphite materials, manufacturers can significantly improve the yield of graphite electrode micro - machining. For example, Kaibo CNC's GJ1417 can help enterprises greatly improve the yield of graphite micro - machining and ensure production stability. If you want to learn more about how to optimize your graphite processing process and improve productivity, click here to explore our solutions.