Essential CNC Milling Machine Maintenance: Guide to Guideway Lubrication and Ball Screw Backlash Inspection

05 12,2025

Tutorial Guide

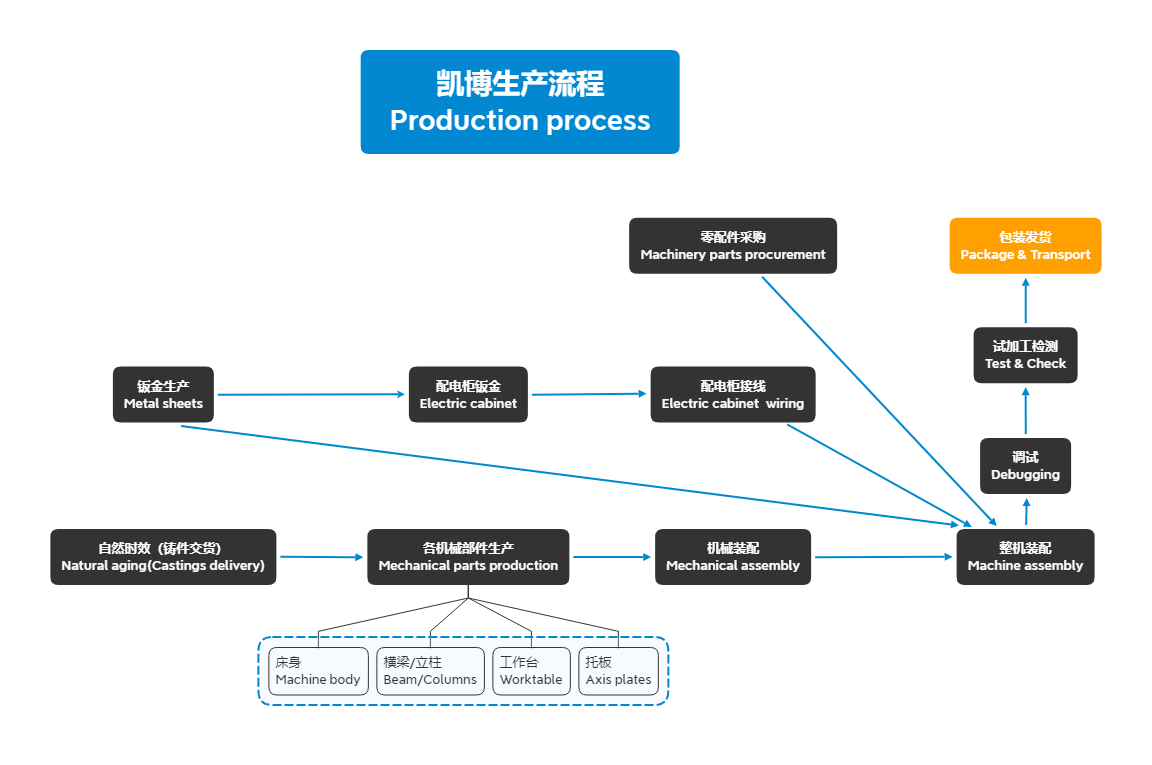

This article provides an in-depth guide on daily maintenance practices for the CNC milling machine DC1317, manufactured by Ningbo Kaibo CNC Machinery Co., Ltd., specializing in plastic mold production. It focuses on key operational techniques such as guideway lubrication scheduling and ball screw backlash inspection, alongside critical maintenance tasks including spindle temperature monitoring and hydraulic system pressure checks. Tailored to the heavy-duty demands of dual-column CNC milling centers, the article presents systematic maintenance strategies and rapid troubleshooting methods to minimize downtime and extend machine lifespan. Combining detailed visual tutorials and video demonstrations with professional after-sales support and technical training, the guide integrates theory and practice to enhance equipment reliability and customer satisfaction.

CNC Milling Machine Daily Maintenance Guide: Practical Tips for Guideway Lubrication & Ball Screw Backlash Inspection

Ensuring the reliable operation of CNC milling machines is critical for maintaining production efficiency and product quality in mold manufacturing. This guide focuses on the daily maintenance best practices for the DC1317 CNC milling machine, manufactured by Ningbo Kaibo CNC Machinery Co., Ltd., a leader specializing in plastic mold machining centers. Home to a robust dual-column structure designed for heavy-duty load, this machine requires systematic upkeep — particularly regarding guideway lubrication, ball screw backlash detection, spindle temperature monitoring, and hydraulic system pressure verification.

1. Guideway Lubrication: Cycle Management & Methodology

The guideway is a vital component influencing machining accuracy and equipment lifespan. A well-lubricated guideway reduces friction, prevents wear, and safeguards against corrosion. For the DC1317, it’s recommended to implement a strict lubrication schedule where:

- Lubricant application occurs every 8–12 operating hours under normal conditions.

- Use high-quality, machine-recommended lubricants with viscosity-grade ISO VG 68–100.

- Apply lubricant at lubrication points marked clearly on the machine, ensuring even coverage along the rail.

- Clean guideways before lubrication to remove swarf and contaminants that accelerate wear.

Neglecting lubrication can increase wear rates by up to 20% and cause positioning errors beyond ±0.02 mm, severely impacting mold precision.

2. Ball Screw Backlash Inspection: Detection & Adjustment Techniques

Ball screw backlash directly affects machining accuracy and surface finish quality. The DC1317’s ball screws must undergo routine inspection every 200 operating hours or monthly, whichever comes first. Follow these essential steps:

- Power off the machine and ensure safety locks.

- Manually move the axis to its mechanical limit to relieve load tension.

- Using a dial gauge positioned on the machine table, gently push and pull the axis in the direction of its movement.

- Measure the backlash value; the acceptable range should be within 0.05 mm for the DC1317.

- If backlash exceeds limits, adjust the preload by tuning the ball screw nut or contacting Kaibo technical personnel for professional recalibration.

Regular monitoring helps avoid cumulative errors that may lead to scrap parts or rework, saving significant operational costs.

3. Additional Critical Maintenance Steps

| Maintenance Item |

Frequency |

Key Points |

| Spindle Temperature Monitoring |

Daily during operation |

Keep temperature below 60°C to prevent bearing damage |

| Hydraulic System Pressure Check |

Weekly |

Maintain pressure within 12–16 MPa for stable tool clamping |

Monitoring these parameters prevents early failures of key components, especially essential for the dual-column frame running heavy mold operations continuously.

4. Recognizing Typical Fault Symptoms and Fast Diagnosis

Operators should be vigilant for early warning signs to minimize downtime:

- Unusual Vibrations or Noise: Usually indicates dry or contaminated guideways or loose ball screws.

- Axis Positioning Drift: May result from excessive backlash or ball screw wear.

- Temperature Spikes in Spindle: Signifies possible bearing wear or lubrication failure.

- Hydraulic Pressure Drops: Could indicate leaks or pump issues affecting clamping force.

Employing a systematic check-list and using diagnostic software integrated with DC1317 greatly streamlines troubleshooting and enhances maintenance responsiveness.

5. Practical Training & Kaibo’s After-Sales Support Services

Recognizing that theoretical knowledge alone is insufficient, Ningbo Kaibo CNC offers comprehensive technical training workshops coupled with responsive after-sales service. Their expert team guides users through customized maintenance schedules, troubleshooting walkthroughs, and advanced diagnostics—even onsite if needed. This hands-on approach ensures equipment uptime maximization and skilled operator empowerment.

Additionally, multimedia resources such as video tutorials and step-by-step guides complement training efforts to reinforce learning and cultivate regular maintenance habits aligned with industrial best practices.

FAQ: Common Questions About DC1317 Maintenance

-

Q1: How often should guideway lubricants be replaced or refreshed?

-

Lubricants generally last between 3 to 6 months depending on machine operation intensity; however, inspection every 500 hours is advised to verify condition and replenish if necessary.

-

Q2: What signs indicate the need for ball screw replacement?

-

Increased backlash over 0.1 mm, visible corrosion, or abnormal noise despite adjustments are indicators that ball screw replacement is due.

-

Q3: Can operators perform hydraulic pressure checks independently?

-

Yes, with proper training and using the prescribed gauges; however, calibration and troubleshooting should involve qualified maintenance personnel.

-

Q4: Does Kaibo provide remote diagnostics service?

-

Yes, Kaibo’s team supports remote monitoring platforms that help diagnose machine status and suggest preventive measures in real time.