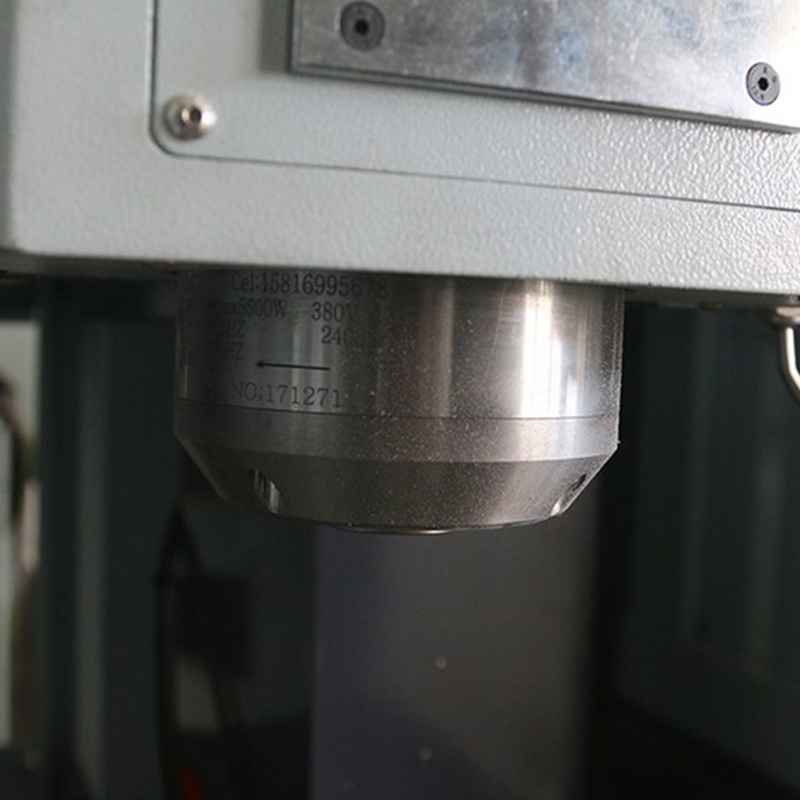

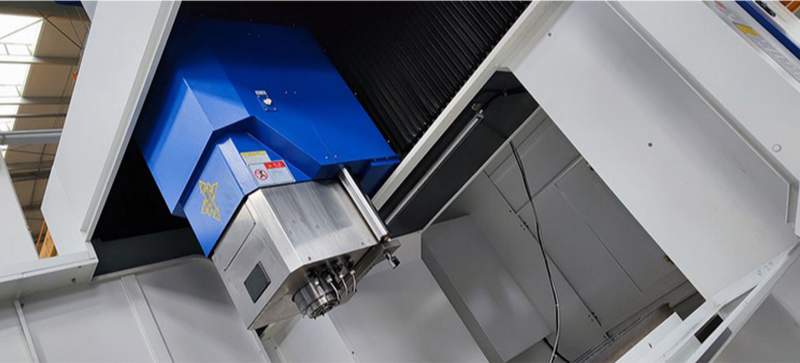

For manufacturers in aerospace, EV battery, and high-performance composites sectors, consistent machining accuracy is not optional—it’s a requirement. The Ningbo Kaibo GJ1417 graphite-specific CNC milling machine delivers precision up to ±0.01mm, but even the best machines need proper care. In fact, over 60% of unplanned downtime in industrial CNC operations stems from poor maintenance—not mechanical failure.

Graphite dust is highly abrasive—just one hour of uncleaned guides can reduce linear rail life by 15–20%. Recommended cleaning frequency: daily for external surfaces, weekly for internal chip paths. Use compressed air (≤6 bar) and non-metallic brushes to avoid micro-scratches on ball screws or guide rails.

For most graphite applications, especially those involving continuous cutting at speeds >15 m/min, we recommend oil mist systems with automatic filters—reducing bearing wear by up to 40% compared to dry methods, based on real-world data from our clients in Germany and South Korea.

If your surface finish drops below Ra 1.6μm or you notice inconsistent tool paths, follow this quick diagnostic flow:

One customer in Dubai reported a 30% drop in part consistency after six months without scheduled inspections. After implementing our recommended monthly checklists—including thermal imaging of motor housings—they regained full tolerance compliance within two weeks.

Whether you’re managing one machine or a fleet, investing time in structured maintenance pays off in reduced scrap rates, longer equipment lifespan, and fewer production delays. That’s why many global OEMs choose Kaibo’s GJ1417 series—not just for its ±0.01mm accuracy, but also for the robust support ecosystem behind it.

Ready to eliminate costly downtime? Explore the GJ1417’s full maintenance protocol + free troubleshooting checklist — trusted by engineers across 30+ countries.