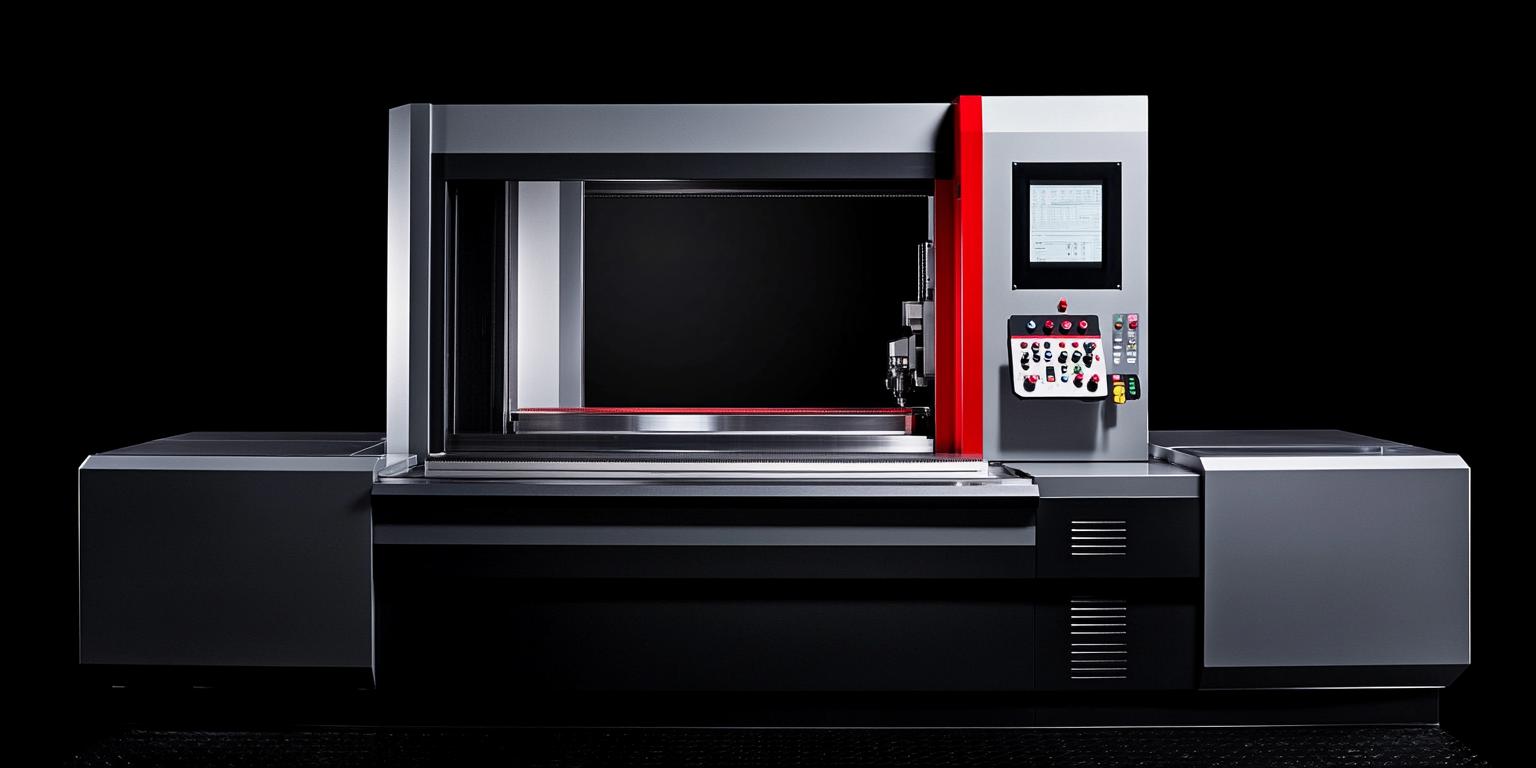

In graphite machining, dust accumulation poses a significant threat to the precision and longevity of CNC milling machines. The Ningbo Kaibo CNC Machinery Co., Ltd. has engineered the GJ1417, a high-precision CNC milling machine specializing in graphite processing. This guide dives deep into daily maintenance practices essential for maintaining the GJ1417’s superior performance and protecting it from graphite dust’s abrasive effects. By establishing a methodical maintenance routine, users can significantly enhance both machine durability and output quality.

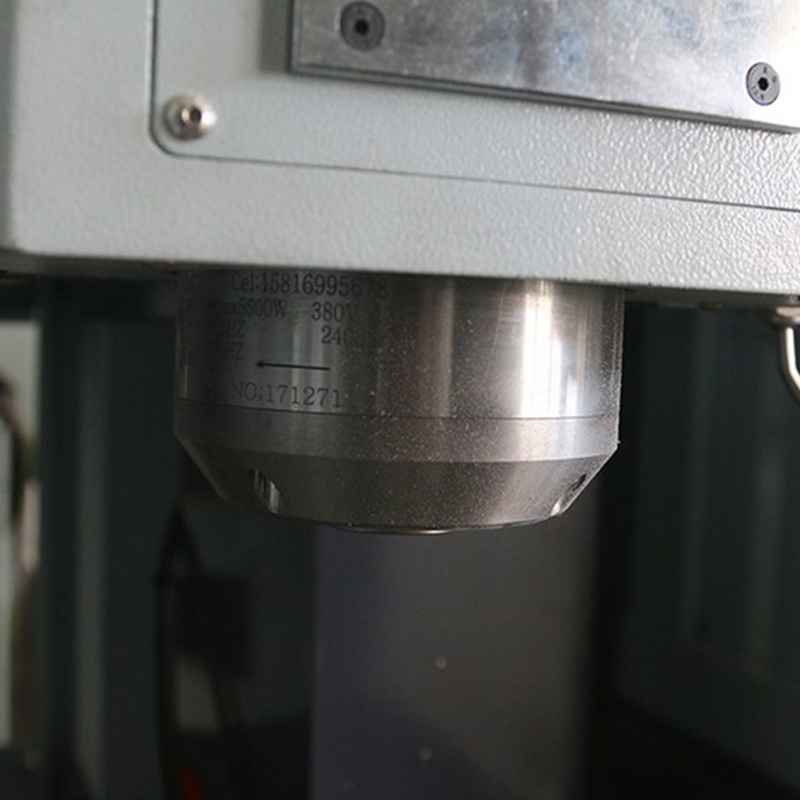

Graphite machining generates ultra-fine dust particles that infiltrate mechanical components such as linear guides, ball screws, and spindles. Left unchecked, this dust leads to increased friction, component wear, and eventual loss of machining accuracy. Research shows that even a 0.01 mm increase in ball screw backlash causes about 10% degradation in machining precision, underscoring the importance of frequent cleaning.

| Component | Cleaning Frequency | Cleaning Method |

|---|---|---|

| Linear Guides | Daily | Use industrial vacuum and lint-free cloth with mild solvent |

| Ball Screws | Every 2 days | Compressed air blowout and wipe with lint-free cloth |

| Spindle | Weekly | Wipe external surface, check for dust ingress via inspection ports |

Lubrication is pivotal for minimizing wear, especially under graphite dust exposure. Two primary lubrication methods are prevalent:

For the GJ1417, the integrated oil mist lubrication system is optimized to balance film thickness and dust adherence, backed by adaptive sensors that modulate lubrication intensity based on operational hours and dust density sensor readings.

Maintaining the precision of key parts requires regular inspection:

| Component | Inspection Interval | Inspection Method |

|---|---|---|

| Linear Guide Clearance | Monthly | Dial gauge measurement; tolerance < 0.02 mm |

| Ball Screw Backlash | Monthly | Dial indicator test; acceptable backlash ≤ 0.01 mm |

| Spindle Runout | Quarterly | Runout gauge; max allowable 0.003 mm |

Frequent issues caused by improper maintenance include surface blemishes, dimensional inaccuracies, and increased noise/vibration:

Implementing a structured fault logic chart streamlines the diagnostic process, enabling rapid pinpointing of root causes backed by historical maintenance data.

The GJ1417's design inherently supports easy access to critical components, reducing maintenance time by up to 30% compared to conventional models, as verified in multiple industrial applications across East Asia. Coupled with Kaibo’s dedicated customer service network, users receive real-time troubleshooting support ensuring minimal downtime and optimized machine availability.

Adopting the recommended maintenance strategy significantly reduces unplanned outages. For example, users report a 25–40% extension in component lifespan and a 15% boost in machining precision stability over 12-month periods when adhering to these practices.

Whether you are a novice operator or an experienced technician, embracing systematic cleaning, lubrication, and inspection protocols for your graphite CNC milling equipment will protect your investment, maximize operational efficiency, and uphold the exceptional machining quality hallmark of the GJ1417 series.