In the realm of graphite machining, the choice of lubrication method for your machine tools is not just a technical detail; it's a critical decision that can significantly impact the precision, longevity, and overall efficiency of your operations. As a factory technical leader or equipment supervisor, you understand the unique challenges that graphite machining presents to machine tool lubrication. Let's delve into the intricacies of two prominent lubrication methods: dry lubrication and oil mist lubrication, and explore which one is better suited for your factory.

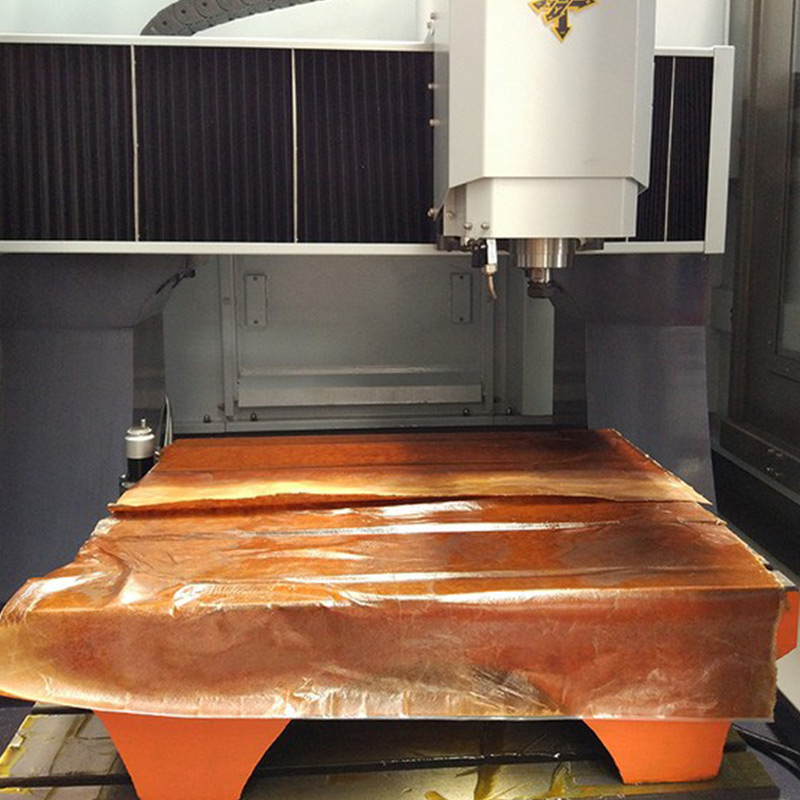

Graphite is a unique material with high hardness and abrasiveness. During the machining process, it generates a large amount of fine dust. This dust can easily adhere to machine components, leading to increased wear, reduced accuracy, and potential breakdowns. Moreover, the lubrication system needs to be able to withstand the harsh environment of graphite machining while maintaining optimal performance.

Dry lubrication, as the name suggests, operates without the use of liquid oil. Instead, it relies on solid lubricants such as graphite or molybdenum disulfide. One of the most significant advantages of dry lubrication is the absence of oil pollution. This not only keeps the working environment clean but also reduces the risk of oil contamination on the graphite workpieces. Additionally, dry lubrication systems typically require less maintenance. With no oil to change or filter, you can save on both time and costs.

In terms of performance, dry lubrication can effectively reduce friction and wear on machine components. Studies have shown that machines using dry lubrication can maintain their accuracy for up to 20% longer compared to those using traditional oil-based lubrication methods. This is particularly important in graphite machining, where precision is crucial.

Oil mist lubrication has its own set of advantages. It provides excellent cooling properties, which can help to prevent overheating during high-speed machining operations. The fine oil mist can also effectively carry away the graphite dust, reducing the risk of dust accumulation on machine parts. This can improve the overall cleanliness of the machine and extend its service life.

However, oil mist lubrication also has some potential drawbacks. There is a risk of oil mist residue remaining on the machine and workpieces, which may require additional cleaning steps. Moreover, the oil mist can pose environmental and health risks if not properly managed. In some regions, strict regulations govern the use of oil mist lubrication due to its potential impact on air quality.

| Lubrication Method | Advantages | Disadvantages |

|---|---|---|

| Dry Lubrication | No oil pollution, low maintenance, long - term accuracy | May have less cooling capacity |

| Oil Mist Lubrication | Good cooling, dust - carrying ability | Oil mist residue, environmental and health risks |

The GJ1417 graphite machining machine is a state - of - the - art device that offers several features that make dry lubrication an ideal choice. Its optimized structure significantly reduces dust accumulation, which is a major concern in graphite machining. With a dry lubrication configuration, the GJ1417 can operate more efficiently, with less risk of breakdowns due to dust - related issues. Additionally, the low - maintenance nature of dry lubrication aligns well with the long - term reliability requirements of the GJ1417.

When choosing a lubrication method, you need to consider your specific operating conditions. If your factory has strict environmental requirements or if you are looking to reduce maintenance costs, dry lubrication may be the better option. On the other hand, if you are performing high - speed machining operations that generate a large amount of heat, oil mist lubrication could be more suitable.

Regardless of the lubrication method you choose, regular maintenance is essential. For dry lubrication systems, check the solid lubricant levels regularly and replace them as needed. For oil mist lubrication systems, ensure proper ventilation and filter replacement to minimize the risk of oil mist residue and environmental pollution.

To illustrate the practical implications of these lubrication methods, let's look at a real - world example. A graphite machining factory in Germany was experiencing frequent breakdowns and poor surface finish on their workpieces due to improper lubrication. After switching to dry lubrication on their GJ1417 machines, they noticed a significant improvement in machine accuracy and a 15% reduction in maintenance costs.

"In our experience, dry lubrication is a game - changer for graphite machining. It not only improves the quality of the workpieces but also reduces the environmental impact," said an industry expert.

In conclusion, the choice between dry lubrication and oil mist lubrication for your graphite machining machines is a complex one that requires careful consideration of your specific needs and operating conditions. By understanding the advantages and disadvantages of each method, you can make an informed decision that will enhance the performance and longevity of your equipment. If you want to learn more about how the GJ1417 and dry lubrication can transform your graphite machining operations, click here to explore further.