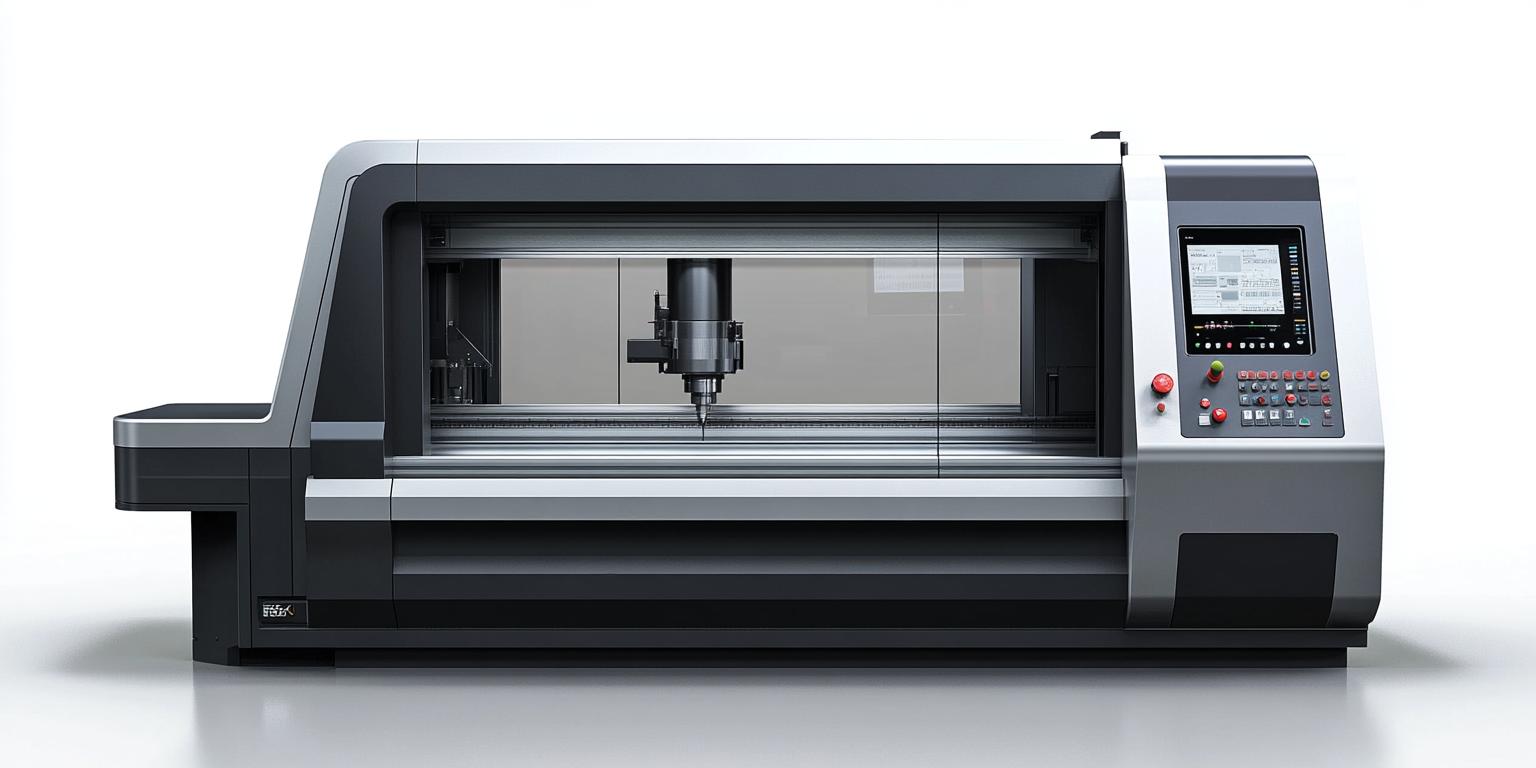

The high - precision CNC milling machine GJ1417, specially designed for graphite machining by Ningbo Kaibo CNC Machinery Co., Ltd., is a remarkable product in the field of graphite processing. However, to ensure its long - term efficient and stable operation, proper maintenance and troubleshooting are essential.

Graphite machining generates a large amount of dust, which can have a significant impact on the accuracy and stability of the machine. When dust accumulates on key components such as the guide rails, lead screws, and spindles, it can cause wear and tear, leading to decreased precision and stability. For example, in a graphite processing factory, if the machine is not properly maintained, the dust may cause the guide rails to wear unevenly, resulting in positioning inaccuracies during machining.

Regular cleaning is crucial to remove dust and prevent it from affecting the machine's performance. For general use, it is recommended to clean the machine at least once a week. The cleaning steps include:

There are two main lubrication methods for graphite CNC milling machines: dry lubrication and oil - mist lubrication. Dry lubrication is suitable for applications where the machine operates at low speeds and light loads. It has the advantage of being clean and reducing the risk of dust adhesion. On the other hand, oil - mist lubrication provides better lubrication for high - speed and heavy - load operations but requires a more complex system and may cause more dust to adhere to the machine.

Regular inspection of key components is necessary to detect potential problems early. The guide rails should be inspected every three months. The straightness of the guide rails should be measured, and the allowable deviation is within ±0.02mm. The lead screws should be inspected every four months, and the backlash should be measured, with a recommended value of less than 0.05mm. The spindle should be inspected every six months, and the run - out should be measured, with an allowable value of less than 0.01mm.

Two common problems in graphite CNC milling machines are "positioning inaccuracies" and "rough surface finish". A systematic troubleshooting process can help users quickly identify the root causes. For positioning inaccuracies, the first step is to check the calibration of the machine. If the calibration is correct, then check the guide rails and lead screws for wear. For rough surface finish, check the cutting tools, spindle speed, and feed rate. A detailed flowchart can be used to guide users through the troubleshooting process.

By following these maintenance and troubleshooting guidelines, users can build a professional operation and maintenance system for their graphite CNC milling machines, improving production quality and efficiency. If you want to learn more about the high - performance GJ1417 graphite CNC milling machine and its excellent after - sales service, click here.