Maintaining high-precision graphite CNC milling machines is crucial for businesses in the manufacturing industry. It not only ensures the accuracy and quality of machining but also extends the service life of the equipment, thereby enhancing the overall competitiveness of enterprises. This guide focuses on the daily maintenance of the GJ1417, a high-precision CNC milling machine dedicated to graphite processing by Ningbo Kaibo CNC Machinery Co., Ltd.

Graphite dust generated during the machining process is one of the most significant threats to the accuracy and lifespan of CNC milling machines. The fine particles of graphite dust can penetrate into the internal components of the machine, such as the guide rails, lead screws, and spindles. Once these particles accumulate, they can cause abrasion, increase friction, and even lead to mechanical failures. For example, dust on the guide rails can cause uneven movement of the worktable, affecting the machining accuracy. Therefore, effective dust cleaning is essential for maintaining the performance of the machine.

The cleaning frequency depends on the intensity of machine use. For machines in continuous operation, it is recommended to perform a basic cleaning after each shift and a thorough cleaning at least once a week. For less frequently used machines, a basic cleaning once a day and a comprehensive cleaning once every two weeks are sufficient.

For beginners, simple cleaning methods such as using a vacuum cleaner with a fine filter can be used to remove surface dust. Advanced users can use compressed air to blow out dust from hard - to - reach areas, followed by wiping with a clean cloth. It is important to note that when using compressed air, the pressure should be controlled to avoid blowing dust into other parts of the machine.

There are two main lubrication methods for CNC milling machines: dry lubrication and oil - mist lubrication. Dry lubrication uses solid lubricants, which have the advantage of being clean and having no oil pollution. However, its lubrication effect may be limited in high - speed and heavy - load applications. Oil - mist lubrication, on the other hand, can provide better lubrication performance, especially in high - speed machining. But it requires a more complex lubrication system and may cause some oil pollution.

| Lubrication Type | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|

| Dry Lubrication | Clean, no oil pollution | Limited lubrication in high - speed and heavy - load | Low - speed and light - load machining |

| Oil - Mist Lubrication | Good lubrication performance | Complex system, oil pollution | High - speed and heavy - load machining |

Regular inspection of key components is also crucial. For guide rails, it is recommended to perform a visual inspection and measure the straightness at least once a month. The lead screws should be inspected for wear and clearance every two months. The spindle, as the core component of the machine, requires a comprehensive inspection every three months, including checking the rotational accuracy and vibration.

When the machine encounters problems, a scientific troubleshooting process is necessary. First, collect information about the fault phenomenon, such as abnormal noises, error messages on the control panel. Then, based on the possible causes, conduct a step - by - step inspection. For example, if the machine has a vibration problem, check the spindle balance, the tightness of the guide rails, and the condition of the cutting tools.

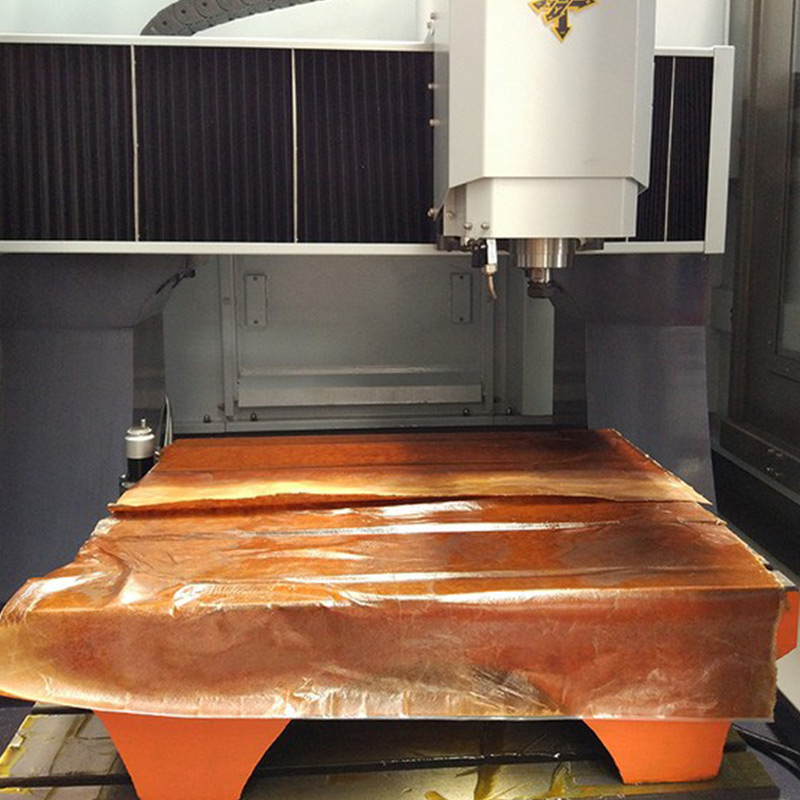

The GJ1417 from Ningbo Kaibo CNC Machinery Co., Ltd. is designed with high precision and durability in mind. It has advanced dust - proof and lubrication systems, which can effectively reduce the impact of dust and ensure stable operation. In addition, the machine is equipped with intelligent monitoring systems that can detect potential problems in advance, allowing for timely maintenance. The company also provides customized services to meet the specific needs of different customers.

By following the maintenance guidelines in this article, users can establish a scientific equipment maintenance system, improve the service life and machining accuracy of the machine, and ensure high - quality production. If you want to learn more about the GJ1417 or need professional CNC milling machine solutions, click here.