In high-precision graphite machining—especially for microstructures like those in semiconductor molds or EDM electrodes—the choice between spiral and straight downcut toolpaths can make or break your yield rate. Many manufacturers overlook this critical detail, leading to unexpected tool breakage, surface defects, and costly rework.

A recent case study from a German precision mold maker revealed that switching from straight to spiral downcut reduced their average tool breakage rate by 40% over three months—without changing cutting parameters or materials. Why? Because straight downcut introduces sharp stress concentration at the entry point, especially in thin-walled parts where rigidity is already compromised.

| Toolpath Type | Stress Distribution | Recommended For |

|---|---|---|

| Straight Downcut | High localized stress → prone to chipping | Thick sections (>3mm), low-tolerance applications |

| Spiral Downcut | Gradual engagement → stable chip removal | Thin walls (<2mm), complex contours, high finish quality required |

For ultra-thin graphite structures (e.g., 0.5–1.5 mm), spiral downcut isn’t just preferable—it’s essential. It allows the cutter to engage material gradually, reducing thermal shock and mechanical vibration that cause premature wear or fracture.

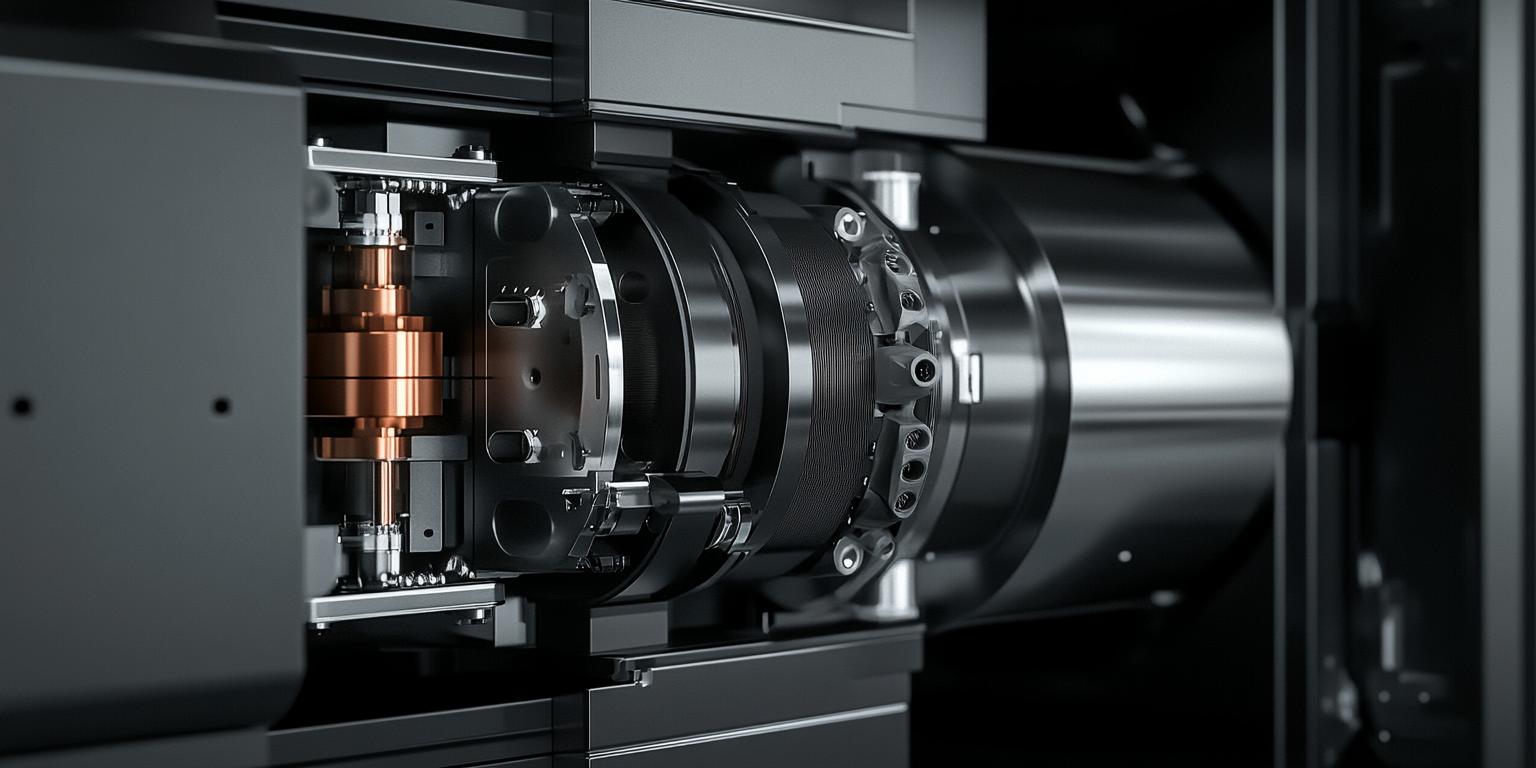

Even with the right toolpath, poor machine stability can undermine results. Our clients using the GJ1417 CNC milling platform report consistent improvements in surface finish and cycle time when combining spiral downcut with dynamic anti-vibration compensation enabled via built-in feedback loops. This system detects minor deflections in real-time and adjusts feed rates accordingly—preventing chatter before it becomes visible.

Additionally, consider material type: natural graphite tends to be more brittle than synthetic grades, requiring lower axial depths per pass (0.1–0.2 mm) and higher spindle speeds (12,000–15,000 RPM). Synthetic graphite allows slightly deeper cuts (up to 0.5 mm) due to its uniform grain structure.

These insights aren’t theoretical—they’re based on actual production data from clients across Europe, North America, and Asia who have adopted these strategies. One U.S.-based battery component manufacturer saw a 30% reduction in scrap rate after implementing spiral downcut protocols for their 1-mm-thick graphite anode holders.

If you're currently struggling with inconsistent finishes or frequent tool failure during graphite machining, ask yourself: Are you using the right approach—or just repeating what worked before?

Download Our Free Guide: "Graphite Machining Best Practices for Precision Parts"